Tackling clinker-reducing conditions

For optimum clinker properties, it is essential that sufficient oxygen is available in the kiln to burn all of the fuel efficiently. An oxygen-deficient atmosphere can result in loss of early strength development and reduced cement flowability.

Reducing conditions can result from insufficient air, excess fuel use, low feed rate, or inadequate grinding of the fuel as well as carbonaceous content in the raw feed. Reducing conditions also increase volatilization of sulfur, which risks built-ups in the kiln preheater and subsequently reduced alkali sulfate in the clinker.

Causes of clinker-reducing conditions

The most common causes include:

- Flame characteristics. If the direction of the kiln flame is down toward the clinker, some of the fuel will be "blown" directly onto the clinker bed. In this situation, the fuel (usually coal) will continue to burn within the clinker bed, leading to localised reducing conditions.

- Incomplete combustion of fuel particles. Large particles of fuel can drop out of the kiln flame into the clinker bed and lead to reducing conditions as described above. These particles can be caused by inappropriate fuel grinding, and are often related to the increase use of alternative fuels.

Identifying clinker-reducing conditions

Watch for conditions such as non-oxidised brown cores within clinker lumps that oxidise on contact with air and become dark. You can also perform a chemical reduction test to identify reduction. To do so:

- Place approximately 10mg of ground clinker in a clean depression of a white ceramic tile.

- Add two drops of solution A (0.25g of 2,2'-bipyridyl dissolved in 90ml of water and 10ml of concentrated hydrochloric acid).

- If a pink colour develops within two minutes, Fe2+ is present and the clinker is strongly reduced.

- If no pink colour develops, add two drops of solution B (50g of tri-sodium citrate dissolved in 100ml of water) and wait a further five minutes.

- If a pink colour then appears, the clinker is moderately reduced.

- If the test is negative, then the clinker has either not been reduced or has been re-oxidised.

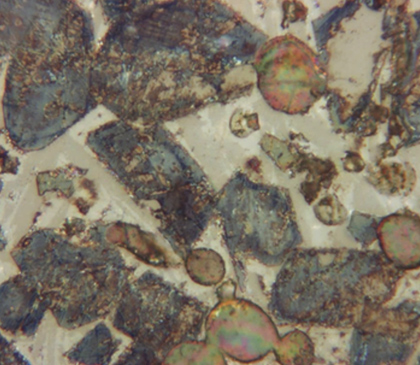

If reducing conditions are not readily evident by seeing brown cores, look at the clinker minerals using microscopy techniques, which more clearly identify reduction if present. Microscopy of reduced clinker will often identify:

- Variable associated features

- Virtual absence of ferrite and alkali sulfate from interstitial phases

- Unstable, poorly defined "rounded" alite-crystal edge conversion to belite

- The presence of aluminate as alkali modified elongated lath-shaped crystals

- Raised LSF, AR, and SR compared to the same clinker in non-reduced form

To prevent reducing conditions:

- Ensure the appropriate raw feed preparation at sufficient fineness, with the correct composition and good homogeneity.

- Verify that you have the proper kiln conditions, including good flame characteristics (including burner alignment), as well as appropriate burning temperature, feed rate, oxygen level, and cooling rate.

- Consider the application of the appropriate cement additive that can mitigate possible negative effects that alternative fuels may have on cement performance.

Learn more about cement additives.