BITUTHENE® 4000

Self-adhesive waterproofing membrane with enhanced bonding characteristics for use with B2 moisture tolerant primer

Product Description

BITUTHENE® 4000 is a flexible, preformed waterproof membrane combining a high performance, cross-laminated, HDPE carrier film with a unique, super sticky, self-adhesive rubber bitumen compound.

Ancillary Products

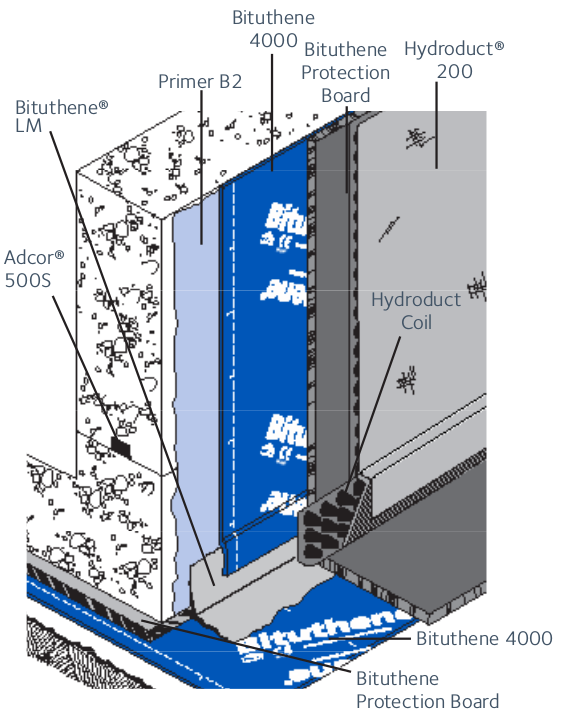

Primer B2

Primer B2 is used to prepare vertical and sloping surfaces and suspended slabs. It is moisture-tolerant and can be used on “green” concrete or damp-to-touch substrates.

Bituthene LM

Waterproof continuity at angles and at penetrations is provided by Bituthene LM two-component, chemically-curing, liquid-applied waterproof membrane..

Bituthene Protection Board

Damage from following trades and backfill is prevented by Bituthene Protection Boards. Located with BitustikTM 4000 double-sided tape.

Product Advantages

-

Cold-applied — simple application to substrates especially at low temperatures.

-

Suitable for application to “green” concrete — reduces programme schedules.

-

Moisture-tolerant primer system — allows application in damp or marginal weather conditions.

-

Wide application temperature range — excellent bond to self and substrate from -10°C to +35°C.

-

Overlap security — enhanced bond provides additional security.

-

Cross-laminated high density polyethylene carrier film — provides high tear strength, puncture and impact resistance.

-

Flexible — accommodates concrete shrinkage cracks.

-

Gas-resistant — methane, carbon dioxide and radon gas protection in excess of the standard membrane requirements in BRE Reports 211 (radon) and 212 (methane and carbon dioxide).

Supply

Bituthene 4000

|

1m x 20m roll (20sq m) 30 cartons/pallet Weight 32kg |

|

| Palletisation | 15 rolls per pallet |

| Storage | Store upright in dry |

| Primer B2 | 5, 25 litre drums |

| Coverage |

10 - 12sq m / litre depending upon method of application, surface porosity and ambient temperature |

Ancillary Products

| Bituthene LM | 5.7 litre packs |

| Bituthene Protection boards | 3mm x 1m x 2m |

| Adcor 500S | 6 x 5m rolls |

| Bitustik 4000 | 150mm x 12m roll |

| Lap Roller | Unit |

| Hydroduct | See separate drainage sheets |

Bituthene 4000 should be brushed onto the surface to ensure good initial bond and exclude air. Adjacent rolls are aligned and overlapped 50mm minimum at side and ends and well rolled with a firm pressure, using a lap roller to ensure complete adhesion and continuity between the layers. On high walls it may be necessary to batten fix the membrane to prevent slippage.

Repairs

Damaged areas to be repaired by patching with an oversize patch applied to a clean dry surface and firmly rolled.

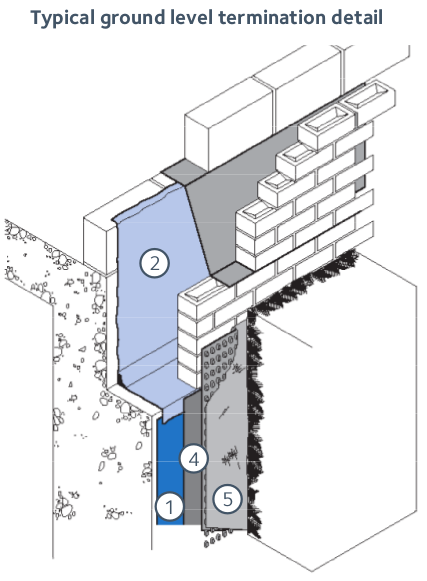

Typical ground level termination detail

Installation

At air temperatures below +4°C measures should be taken to ensure that all surfaces are free from ice or frost.All surfaces except those below ground bearing slabs and PREPRUFE® R membranes should be primed with one coat of Primer B2 applied at a rate of approx. 10m2 / L. Bituthene 4000 shall be laid by peeling back the protective release paper and applying the adhesive face onto the prepared surface, free from ice, frost, condensation or any contaminants which could adversely effect adhesion. Bituthene LM to be applied at all internal and external corners, penetrations etc. prior to applying the overall membrane.

Details shown are typical illustrations only and not working drawings. For assistance with working drawings and additional technical advice please contact your local GCP representative

Physical Properties

| Property | Typical Value | Test Method |

|---|---|---|

| Elongation at max load |

Long 244% Trans 185% |

BS 2782 320 A |

| Tear resistance |

Long 77N Trans 92N |

MOAT 27:5.4.1 |

| Peel strength | 76.5N / mm2 | MOAT 27:5.1.3 |

| Tensile strength of joints | 117N | MOAT 27:5.2.2 |

|

Moisture vapour permeability |

0.31g / m / 24 hours |

BS 3177: 1959 (75% RH/25oC) |

| Puncture resistance | 220 N 65mm | ASTM E154 |

|

Water resistance (6m head) |

No penetration | MOAT 27:5.1.4 |

| Environmental resistance | Conforms | ASTM D543 |

Performance

Bituthene 4000 complies with the relevant section of the following national standards:

BS 8102:1990, Building Regulations (England and Wales) 1991 (amended 1994) clause C4. Building Regulations (Northern Ireland) 1994 (amended 1995) clause B2. Building Standard (Scotland) Regulations 1990, Regulation B2.1, G2.6.

Health and Safety

There is no legal requirement for a Material Safety Data Sheet (MSDS) for Bituthene 4000, Bituthene Protection Boards, Bitustik, Lap Roller, Hydroduct or waterstops. For health and safety questions on these products please contact GCP Applied Technologies.

For Primer B2, and Bituthene LM read the product label and MSDS before use. Users must comply with all risk and safety phrases. MSDS can be obtained from GCP Applied Technologies.

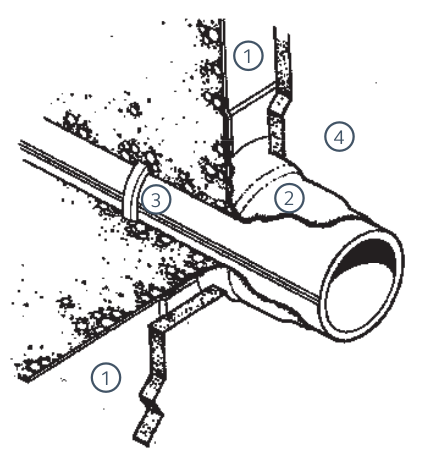

Pipe through wall detail

1 Bituthene 4000 on Primer B2

2 Bituthene LM

3 Adcor 500S

4 Bituthene Protection Board

5 Hydroduct 220

NBS Specification Clause

Refer to Clause 180 and 190.

Technical Services

For assistance with working drawings for projects and additional technical advice, please contact GCP Applied Technologies.

gcpat.hk | For technical information: enquiry.hk@gcpat.com

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

Biuthene, Adcor, Preprufe and Hydroduct are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies, Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Alpharetta, GA 30009, USA

GCP (Hong Kong) Ltd., 6 On Chuen Street, On Lok Tsuen Ind Area, Fanling, Hong Kong

This document is only current as of the last updated date stated below and is valid only for use in Hong Kong. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.hk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-07-21

https://gcpat.hk/en-gb/solutions/products/bituthene-post-applied-waterproofing/bituthene-4000