ELIMINATOR® bridge deck waterproofing membrane

Extending the life of road and railway bridges

Superior protection for bridge decks

Steel and concrete bridges are vulnerable to attack by water, chloride and frost, leading to deterioration and even structural failures. Installing a high-performance waterproofing membrane is therefore an essential part of any bridge construction or refurbishment program. The ELIMINATOR® bridge deck waterproofing membrane is a cold, spray-applied solution that can outlast the life of the structure — reducing maintenance costs and traffic disruptions.

ELIMINATOR® Product Documents

| Product Name | Product Data Sheet |

| BOND COAT 3 | |

| BOND COAT SA1030 | |

| ELIMINATOR® Waterproofing Membrane | |

| PA1 PRIMER | |

| TACK COAT NO.2 | |

| ZED S94 |

Products

- Product Name

- Description

- Key Benefits

- Applications Type

BOND COAT 3 represents a major step forward in the provision of high performance heat-activated tack/bond coats, providing adhesion between the ELIMINATOR® bridge deck waterproofing membrane and a wide range of asphalt surfacing mix designs.

- Suitable for a wide range of asphalt specifications including 'high stress' sites providing an excellent bond between ELIMINATOR® and asphalt pavements.

- Exceeds the enhanced adhesion requirements as specified in Highways Agency IAN96/07 Rev. 1.

- Approved for use with the Eliminator bridge deck waterproofing membrane by:

- EOTA – ETA No.15/0362, Liquid Applied Bridge Deck Waterproofing, ETAG 033

- British Board of Agreement (UK) - HAPAS Certificates No.11/H169, 11/H170, for Highways England road bridges.

BOND COAT 3 is applied on to the ELIMINATOR® membrane to provide a strong bond between the membrane and subsequent bituminous surfacing. It is suitable for use with most types of hot-applied bituminous road surfacing including those where the bitumen content in the surfacing specification is low and/or where the surfacing layer is thin1.

BOND COAT SA1030 is a hot melt adhesive bond coat based on a polymer modified bitumen.

- Provides an excellent bond between the asphalt surfacing and ELIMINATOR®.

- Solidifies rapidly after application.

- Increases contact at the asphalt/membrane interface .

BOND COAT SA1030 is applied to GCP Applied Technologies’ ELIMINATOR® waterproofing membrane to provide a bond between the bituminous surfacing and the membrane . It is recommended where the bitumen content is low, void content is high or where aggregate segregation may occur.

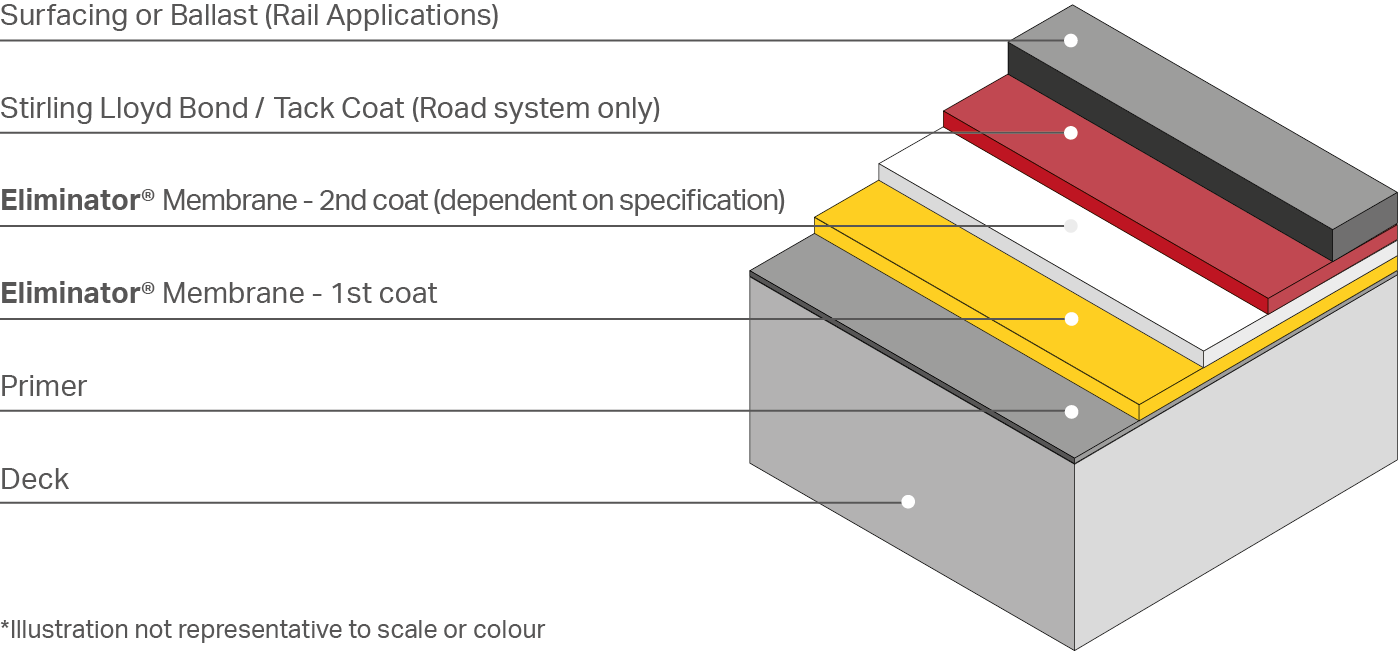

ELIMINATOR Waterproofing Membrane is a GCP Applied Technologies (“GCP”) high performance system for the protection of concrete and steel decks. ELIMINATOR Membrane is based on GCP’s (formerly Stirling Lloyd’s), unique ESSELAC advanced resin technology and extensive experience in the development of coatings for specialist waterproofing. ELIMINATOR Membrane cures rapidly to provide a tough, flexible seamless coating and has an unparalleled track record with thousands of structures waterproofed successfully throughout the world.

- Single source system. High performance GCP (formerly Stirling Lloyd) proprietary primers and tack coats promote secure adhesion between substrate and surfacings on highway bridges, piers and other critical highway components

- ELIMINATOR Membrane can be applied at temperatures between -10ºC and + 50ºC without any loss in performance.

- Unparalleled track record of success

- Concrete Bridge Decks

- Steel Bridge Decks

- Bridge Piers

PA1 PRIMER is a single-component, air drying primer for concrete and cement screeds, enabling application in temperatures as high as 50°C. PA1 PRIMER is based on GCP Applied Technologies’ advanced resin technology and extensive experience in the development of high performance primers.

PA1 PRIMER is used to seal the surface of concrete screeds and to improve the adhesion of GCP’s wide range of membranes, screeds and coatings.

Approved for use with the Eliminator bridge deck waterproofing membrane by:

- EOTA – ETA No.15/0362, Liquid Applied Bridge Deck Waterproofing, ETAG 033

- British Board of Agreement (UK) - HAPAS Certificates No.11/H169, 11/H170, for Highways England road bridges.

PA1 PRIMER is used to seal the surface of concrete screeds and to improve the adhesion of GCP’s wide range of membranes, screeds and coatings.

TACK COAT NO.2 is a cold applied, one component, high strength adhesive based on GCP’s unique ESSELAC® advanced resin technology and extensive experience in the development of high performance tack and bond coats.

- Provides an excellent bond between the surfacing and ELIMINATOR®.

- Contrasting colour for easy application.

- Heat activated by the asphalt surfacing temperature.

TACK COAT NO.2 is applied to GCP’s ELIMINATOR® waterproofing membrane to provide a bond between the membrane and the bituminous road surfacing. It is recommended specifically for applications where Sand Carpet asphalt to BS594: Part 2: 2003, mastic asphalt and Gussasphalt are specified.

ZED S94 is a single-component, anti-corrosive air-drying metal primer.

ZED S94 is used on steel (including galvanised steel) and other metallic surfaces to enhance the bond between GCP’s ESSELAC® resin based systems and the metal substrate.

Achieve long-term performance

The ELIMINATOR® bridge deck waterproofing membrane has an unparalleled track record protecting thousands of concrete and steel bridges throughout the world. Based on unique ESSELAC® advanced resin technology, the system creates composite action between the deck, waterproof membrane, substrate and asphalt, ensuring that the membrane is fully bonded both downwards to the deck and upwards to the surfacing. The extremely high bond enables the membrane to stand up to punishing climate conditions and heavy traffic loads.

Accelerating waterproofing application

The ELIMINATOR® bridge waterproof membrane offers fast, simple and effective application. Unlike alternative solutions that are sensitive to moisture, the ELIMINATOR® membrane can be applied virtually year round, in any climate, preventing costly weather delays. It cures in just an hour, even in high humidity or low temperatures. In addition, the system features on-the-spot QA capabilities, such as the two-color application system, that make it easy to quickly verify that the membrane is applied properly.

Product Advantages

- Long lasting, highly durable membrane drives down future maintenance costs

- Fast application (in excess of 2,000m2 per day) with industry-standard equipment

- No need for hot trades

- Requires minimal surface preparation

- Approved Contractor Program and onsite quality control measures ensure the integrity of the membrane prior to surfacing

- Elimination of critical overcoating time allows phasing of work for greater scheduling flexibility

- Unaffected by application of surfacing up to 250°C